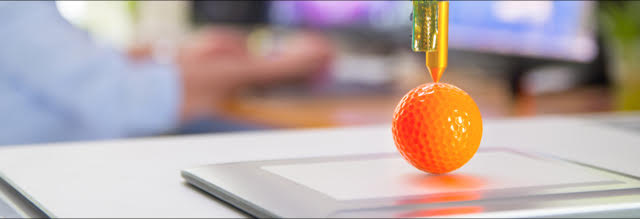

You may have heard of a new type of printing called “three-dimensional (3D) printing.” Instead of printing ink on a piece of paper or plastic, the 3D printer actually makes a three-dimensional object. These printers are now available for home computers (starting at only $283), so you can now manufacture virtually any shape for any use right in your own home.

When I first saw this on TV several years ago, once I got over my disbelief my first question was, “What material are they using to make these objects and is it toxic?

Recently others have been asking this question too, and there is starting to be some research results to look at.

The majority of desktop 3D printers designed for the consumer market use a technology called fused filament fabrication (FFF), also known as molten polymer deposition (which sounds more descriptive to me). In this process, a slender thread of solid thermoplastic is melted and deposited in thin layers onto a moving bed. The three-dimensional solid shape is formed layer-by-layer as the plastic material cools and hardens. That makes logical sense to me, but the first time I saw it, it looked like magic.

A wide variety of filament materials are now being used in desktop FFF 3D printers, including

- acrylonitrile butadiene styrene (ABS)

- poly(lactic acid) (PLA)

- poly(vinyl alcohol) (PVA)

- polycarbonate (PC)

- high-density polyethylene (HDPE)

- high-impact polystyrene (HIPS)

- nylon

- and many other polymers, metals, ceramics, and other materials.

Filaments are melted at a variety of extruder nozzle temperatures and bed temperatures, and manufacturers typically recommend ranges of optimal temperatures for each filament material and thickness. These varying temperatures affect the amount of volatile organic chemicals (VOCs) and particles that might be released from the materials as well as their toxicity.

Two studies have generated quite a lot of data on this subject, which I’m not going to attempt to summarize here.

I just do want to mention that one study identified gasses that were released, which included ammonia, cyanidric acid, phenol, and benzene, among others.

Overall, lab tests showed that ABS is significantly more toxic than PLA, but the corn-based PLA had it’s own emissions when extruded at temperatures higher than 392 degrees F. This is important to note because there are many finished consumer products made from PLA that would not have emissions because they are at room temperature.

It was also noted that the same material spools, when acquired from different resellers, release very different quantities of VOCs, even if used in the same 3D printer and under the same parameters of speed and temperature. So there is a wide variation of air pollutants that could be present as the result of using a 3D printer.

Health effects mentioned were pulmonary problems, such as bronchitis, tracheitis, and asthma. In some cases, outgassing substances were known cause certain types of cancers.

Researchers recommend using 3D printers in a well-ventilated area.

3D PRINTING INDUSTRY: How Toxic are ABS & PLA Fumes?

3D PRINTING INDUSTRY: Gas evolution during FDM 3D printing and health impact